PRODUCTS

Trimer’s Resin Systems are designed specifically for industrial production processes. Each product line offers tailored material properties to fit the needs of our customers manufacturing process. This allows Trimer to offer value-added process development to suit the individuals needs for both product performance and cost.

HARP - Rapid

The RAPID resin system is developed to rapidly cure parts using HP-RTM production methods.

HARP - SPARX

The SPARX resin system is flameproof and self extinguishing while containing no toxic additives.

HARP - N-FUZE

The N-FUZE resin system rapidly infuses reinforcements maximizing wetting and reducing void content.

HARP - NSL8

The N-SL8 resin system has an extremely high glass transition temperature and low thermal conductivity making it ideal for design of thermal barriers.

HARP - ARC

The ARC line of resins are highly electrically resistive with minimal shrinkage. Ideal for potting and encapsulation of electronics.

HARP - PULL

The PULL line of resins incorporates internal mold release agents reducing friction allowing smooth continuous Pultrusion production at rates exceeding 5 ft/min.

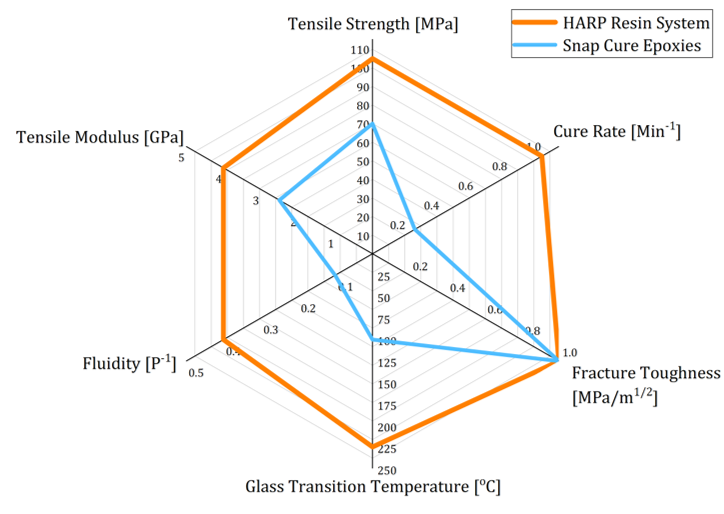

Material Properties Comparison

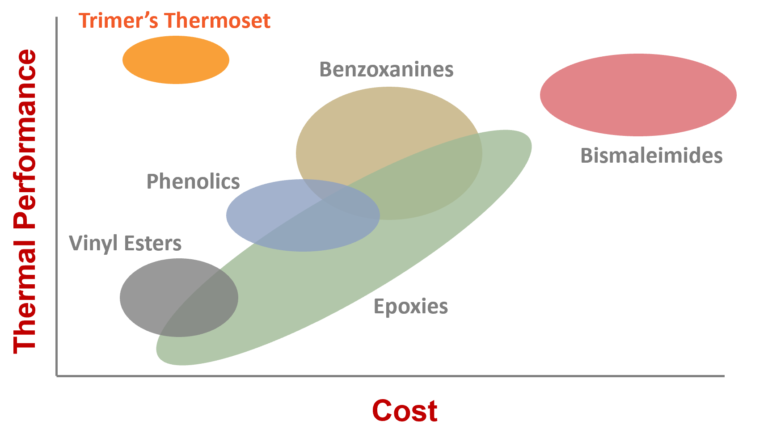

Trimer’s resin systems provide a revolutionary set of materials properties that are unmatched by state-of-the-art resins, offering a unique value proposition and can enable reduced manufacturing cost while increasing material performance.

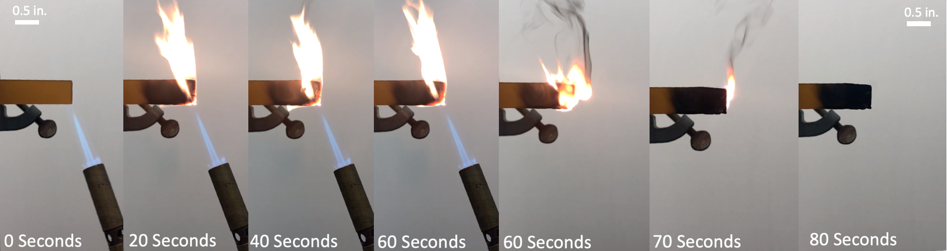

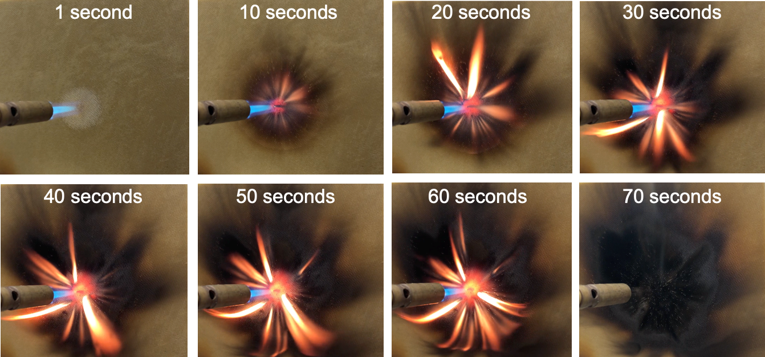

Non-Flammable Polymers

Trimer can provide resin systems with inherent resistance to fire without the need for toxic halogenated compounds or rheology modifying inorganics. Trimer’s resins offer both low viscosity and non-flammability which enable RTM manufacturing of composites suitable for applications requiring extreme FST performance.

Thermally Stable Polymers

Our polymers provide high glass transition and decomposition temperature ensuring performance in the most extreme environments. The high glass transition temperature can be achieved through a cure as short as 45 sec opening the door to low cycle time manufacturing of components that previously required costly resins with long cure times and typically requiring processing in an autoclave.

Contact us

To find out more about Trimer’s resin systems or to get a detailed data sheet for a specific resin, send us a brief message and our team of motivated engineers will be in contact to help you implement our products.