MARKETS

Trimer’s Resin Systems are designed to meet the needs of the most challenging applications across a broad range of markets. Trimer can develop a value-added solution for your particular application, whether it be reducing production time, improving thermal stability, providing fire resistance or simplify enabling composites with greater stiffness and durability.

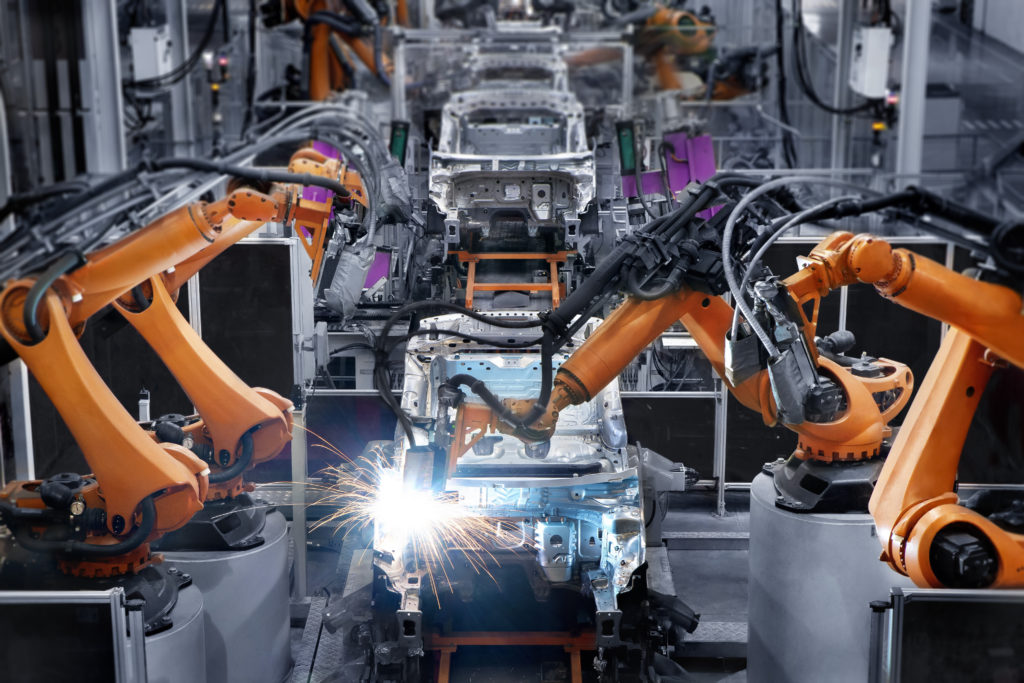

Automotive

The automotive industry is driven by manufacturing efficiency and cycle time. Trimer’s RAPID resin system for HP-RTM, RTM, and liquid Compression molding can achieve cycle times under one-minute enabling continuous fiber composites to be be applied to high-volume platforms with reduced cost and tooling.

Wind Energy

Trimer’s N-FUZE resin system has a low room temperature viscosity and long gel-time to speed the infusion of large parts, followed by a cure in minutes rather than hours. The N-FUZE resin system can reduce molding time thereby increasing manufacturing capacity and minimizing the levelized cost of energy.

Trimer’s PULL resin allows increased pultrusion line speed providing lower manufacturing cost and greater volume.

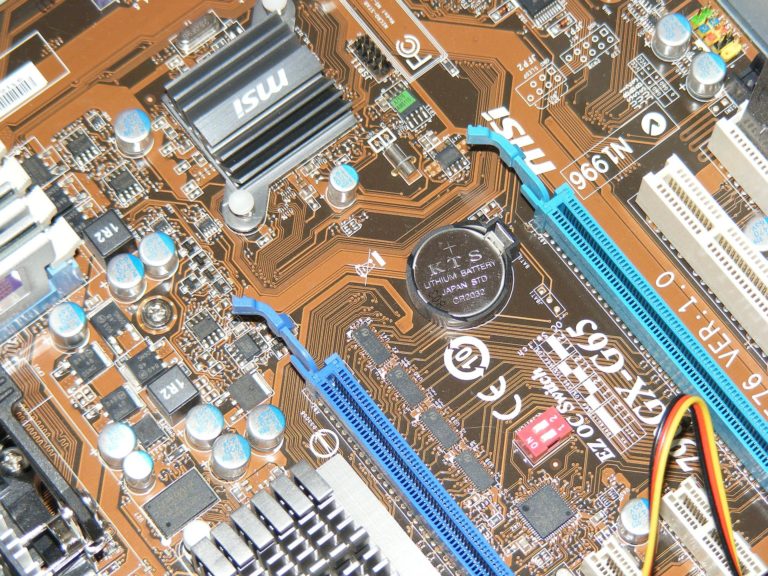

Electrical Insulation and Potting

Trimer’s ARC resin system offers high dielectric strength, low viscosity and incredible thermal stability to work in the most challenging applications. Transformer and motor windings can be rapidly infused to increase reliability or thermally conductive potting compounds can be used to package electronics. The ARC resin system is non-flammable and offers high thermal stability enabling use around batteries, high power electronics or high temperature components.

Fire Protection

Trimer’s SPARX resin system offers inherent non flammability without costly additives to halogenated compounds that produce toxins when burn meeting the most demanding applications. Once cured, the SPARX polymer exceeds the flame spread (ASTM E162), smoke density (ASTM E800) and smoke toxicity (ASTM E662) of MIL-STD-2031 for submarines, as well as FAR 25.853 for vertical flame spread. Trimer’s SPARK resin is ideally suited for aircraft interiors, ships, mass transit, rail, construction and numerous others.

Defense

Trimer’s HARP family of resin systems offer wide ranging performance for the complex and high value systems used by the defense industry. Our polymers provide aerospace grade properties with automotive manufacturing efficiency. Aircraft primary structures, battery enclosures, rocket motor cases, pressure vessels, ablation resistant thermal protection systems are among the applications our resins have been applied to.

Oil and Gas

Trimer’s HARP family of resin systems provide the thermal and chemical stability required for downhole applications. Our PULL resin system can be used for downhole wiring, while our RAPID system is ideal for frack plugs and frack balls. Trimer’s resins are ideal for protecting critical investments in the most challenging oil and gas applications.

Structural

Trimer’s HARP family of resin systems can be used to manufacture fire resistant structures. We have used RAPID to manufacture non-flammable composite wood products which can provide increased safety and piece of mind.

Contact us

To find out how Trimer can increase your manufacturing efficiency, provided increased mechanical or thermal properties, send us a brief message and our team of motivated engineers will be in contact to help you implement our products.